VDL Systems opens additional production facility in Eindhoven

After previous expansions at our facility in Uden, VDL Systems will have a second production location in Eindhoven as of the 1st of September. Due to the growth of our organisation, there was a strong need for additional production space and personnel. The expansion to Eindhoven now enables VDL Systems to facilitate the growth of our partners even better.

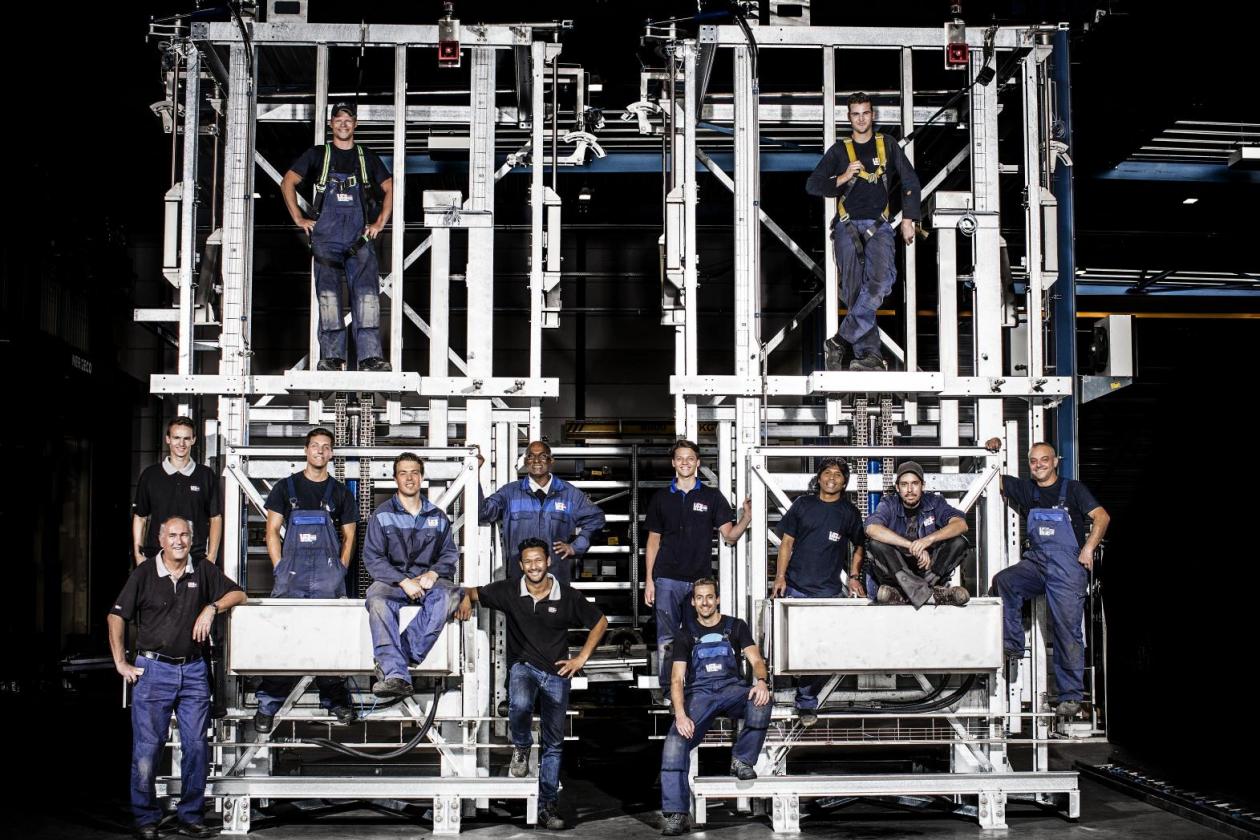

The new building at Wekkerstraat 1 was used by VDL Lasindustrie until the middle of this year. This sister company specializes in high-quality sheet metal processing and welding, with a focus on steel and aluminum. These business activities were recently integrated with VDL HMI in Helmond, together with a small part of the staff. However, the majority of the staff (44 employees) will now be employed by VDL Systems and will focus entirely on stainless steel machine construction, mainly for the food industry.

In the past months, the factory in Eindhoven has been working hard on the conversion to a factory that is fully focused on the processing of stainless steel. The new VDL Systems Eindhoven has a production area of 7,000m², which increases the total floor space of VDL Systems to approximately 28,600m². The new location already has a laser cutting machine and press brakes for stainless steel sheet metal processing, but the focus here will be on stainless steel welding and construction work. A glass bead blasting cabin will be installed later this year, so that both from our welding department in Uden and the one in Eindhoven, fully finished welded constructions can be transported to the customer or our assembly department in Uden.

In the past five years, three new assembly halls have been built and equipped at the current location in Uden. However, after these investments, there was still an urgent need for additional staff and space for the production of machines and systems for the food industry. Therefore, the current expansion at Wekkerstraat 1 offers us the opportunity to be able to meet the needs of our customers even better.

VDL Systems

VDL Systems in active in engineering, production and installation of machines, production lines and internal logistic systems for OEM’s of food processing equipment. As sub-supplier for the food processing industry, VDL Systems in specialized in processing stainless steel, plastics and aluminum. We provide everything from CAD/3D-engineering, to complete turnkey production within the walls of our own organization.